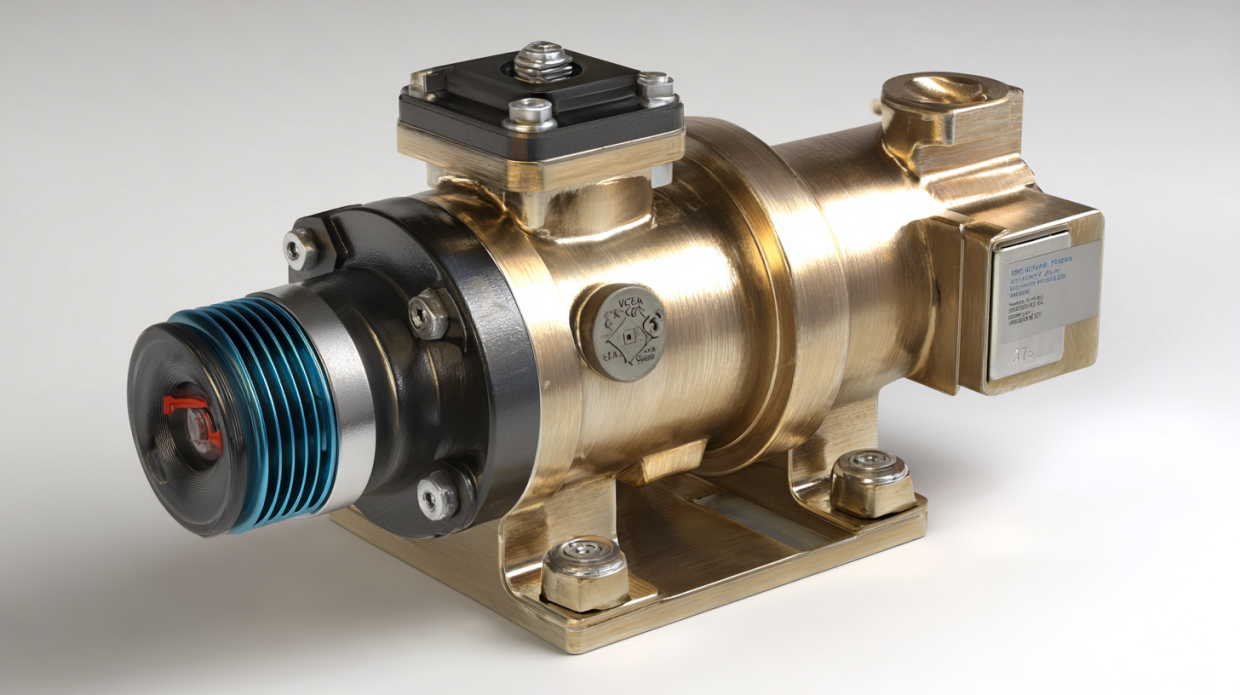

Jabsco 12V DC Macerator Pump for RVs/Boats – Efficient 43 L/min Waste Transfer for Black Water Tanks Up to 200 Gallons – Compact Design, 4-Blade Chopper, Self-Priming, Dry-Run Protection

- Transform black water handling with the Jabsco macerator pump, grinding waste into smooth slurry for stress-free sewage disposal; enjoy efficient, clean solutions tailored to enhance your on-the-go comfort and convenience.

Navigating the World of Marine Waste Management with Confidence

In the realm of marine sanitation, few components are as crucial yet misunderstood as the humble macerator pump. Whether you’re a seasoned sailor or a weekend warrior on the water, understanding this vital piece of equipment can make the difference between smooth sailing and a voyage fraught with unpleasant complications. Join me as we dive deep into the world of Jabsco macerator pumps—the unsung heroes of marine waste management.

As someone who has spent countless hours troubleshooting, installing, and maintaining these devices on vessels of all sizes, I’ve developed both a deep appreciation for their engineering and a practical understanding of their quirks. This comprehensive guide aims to share that knowledge, helping you navigate the sometimes murky waters of marine sanitation with confidence and expertise.

What Exactly Is a Jabsco Macerator Pump?

At its core, a Jabsco macerator pump is a specialized marine pump designed to handle waste efficiently in boat sanitation systems. Unlike standard pumps, a macerator pump doesn’t just move waste—it transforms it, grinding solid materials into a fine slurry that can be easily discharged without clogging pipes or creating blockages.

The name “macerator” comes from the Latin word “macerare,” meaning to soften or break down. And that’s precisely what these ingenious devices do. Picture a powerful blender designed specifically for waste management, capable of processing toilet paper, human waste, and other materials that would normally clog conventional pumps.

Jabsco, a brand under the Xylem Inc. umbrella, has become nearly synonymous with marine macerator pumps over the decades. Their reputation for reliability and performance has made them the go-to choice for boaters worldwide, from small pleasure craft to substantial yachts.

The typical Jabsco macerator pump features a durable housing, usually made from high-quality plastic or marine-grade materials designed to withstand the harsh conditions of marine environments. Inside this housing sits the heart of the system: a stainless steel cutting plate working in conjunction with a chopper blade that rotates at high speed to effectively macerate waste.

The Inner Workings: How Does a Jabsco Macerator Pump Function?

Understanding how your macerator pump works is the first step toward proper maintenance and troubleshooting. The operation is deceptively simple but remarkably effective.

When activated, the electric motor drives an impeller that creates suction, drawing waste from your holding tank. As this waste enters the pump chamber, it encounters the business end of the macerator—a set of rotating cutters that chop and grind solid materials into tiny particles. This transformation is crucial, as it allows waste to be pumped through narrower discharge hoses without clogging.

The macerating action happens courtesy of a chopper blade rotating against a fixed cutting plate. This combination works similarly to a garbage disposal in your home kitchen but is specifically engineered for marine waste. The ground waste is then expelled through the discharge port, typically using a 1-inch or 1.5-inch hose that carries it to the discharge thru-hull fitting.

Jabsco’s engineering shines in the details. Their pumps typically feature self-priming capabilities up to about 4 feet (1.2 meters), meaning they can draw waste even when positioned above the holding tank—a common configuration in many boats. Most models operate on 12-volt DC power, drawing between 10-15 amps during operation, making them compatible with standard boat electrical systems.

The Undeniable Benefits of Using a Jabsco Macerator Pump

The advantages of incorporating a Jabsco macerator pump into your marine sanitation system extend far beyond mere convenience. These benefits explain why they’ve become standard equipment on countless vessels worldwide.

Efficient waste management is the cornerstone of comfortable boating, particularly during extended voyages or when navigating with a full crew. Without an effective macerator pump, you’re limited in how you can handle onboard waste—often resulting in unpleasant odors, frequent pump-out station visits, or complicated manual processes.

One of the primary benefits is the ability to discharge waste legally in appropriate locations. While regulations vary by region (and it’s critically important to familiarize yourself with local laws), a macerator pump gives you the option to discharge treated waste when permitted, extending your time between pump-out facility visits.

The pump’s grinding action also provides protection for your entire waste system. By reducing solids to tiny particles, you’ll experience fewer clogs in discharge hoses and thru-hulls. This reduction in blockages means less maintenance and fewer emergency situations—something every boater can appreciate.

Additionally, Jabsco macerator pumps are designed with versatility in mind. Beyond their primary purpose of emptying holding tanks, they can be used for various other applications, including:

- Shower sump evacuation

- Fish box drainage

- Bilge pumping (though specialized bilge pumps are generally preferred)

- General liquid transfer where some solid content may be present

Their robust construction delivers reliability even in demanding marine conditions. Most models feature thermal overload protection that automatically shuts down the pump if it overheats—a valuable safeguard against damage during extended operation or if the pump runs dry.

Installation Essentials: Setting Up Your Jabsco Macerator Pump

Installing a macerator pump might seem daunting, but with proper planning and attention to detail, it’s a project well within the capabilities of a reasonably handy boater. If you’re not comfortable with marine plumbing or electrical work, however, hiring a professional is always a wise investment.

Before beginning installation, gather all necessary components:

- The Jabsco macerator pump itself

- Appropriate marine-grade hoses (typically 1.5″ for intake and 1″ for discharge)

- Stainless steel hose clamps

- Wire for electrical connections

- Fuse holder and appropriate fuse (typically 15-20 amp)

- Switch for operation

- Mounting hardware

- Anti-siphon valve (if required by your configuration)

Location selection is critical. The pump should be mounted as close to the holding tank as possible to minimize intake hose length. Ensure the location remains dry and allows access for maintenance. Many boaters install their macerator pump in a locker or compartment near the holding tank.

For the installation process:

- Mount the pump securely using stainless steel fasteners, ensuring it’s oriented correctly with the intake port facing the holding tank.

- Connect the intake hose from the holding tank to the pump’s inlet port using two stainless steel hose clamps at each connection for security.

- Connect the discharge hose to the outlet port, again using double hose clamps. Route this hose to your discharge thru-hull fitting.

- Wire the pump to your electrical system, ensuring you include the appropriate fuse for protection. Most Jabsco models require a 15-amp fuse for 12V DC operation.

- Install a switch in an accessible location for operation. Many boaters prefer a momentary switch that must be held down during operation to prevent accidental discharge.

- If required by your configuration, install an anti-siphon valve in the discharge line to prevent backflow.

- Test the system with clean water before actual use to verify proper operation and check for leaks.

The entire installation typically takes 2-4 hours, depending on your boat’s configuration and your familiarity with marine systems. Take your time with hose routing—avoid sharp bends that could restrict flow, and ensure all connections are absolutely secure to prevent leaks.

The Primary Purpose: Why Boaters Need Macerator Pumps

The fundamental purpose of a Jabsco macerator pump extends beyond simple convenience—it’s about creating a functional, hygienic, and environmentally responsible waste management system for your vessel.

On boats, space comes at a premium, and waste holding tanks have finite capacity. A macerator pump allows you to empty your holding tank when appropriate, extending your time between visits to pump-out facilities. This capability is particularly valuable for cruisers who may spend extended periods away from marinas or for boats with limited holding tank capacity.

It’s important to emphasize that responsible waste discharge is governed by strict regulations that vary by location. In the United States, for example, the Clean Water Act prohibits the discharge of untreated sewage within three miles of shore. Similar regulations exist worldwide. A macerator pump doesn’t exempt you from these regulations—it simply gives you the mechanical ability to comply with them when legal discharge is permitted.

Beyond regulatory compliance, macerator pumps serve several practical purposes:

- They transform solid waste into a liquid slurry that can pass through smaller diameter discharge hoses without clogging.

- They reduce the likelihood of holding tank sensors becoming fouled by solid waste.

- They minimize the risk of blockages in the entire waste system, from holding tank to discharge port.

- They provide an emergency option for emptying a holding tank when pump-out facilities aren’t available (where legally permitted).

For liveaboards and long-distance cruisers, a reliable macerator pump isn’t just a convenience—it’s a necessity for maintaining sanitary conditions onboard. The ability to efficiently manage waste contributes significantly to the comfort and health of everyone aboard.

Troubleshooting Guide: When Your Jabsco Macerator Pump Isn’t Performing

Even the most reliable equipment occasionally experiences issues, and macerator pumps are no exception. Knowing how to diagnose and address common problems can save you considerable time, money, and frustration.

Problem 1: Pump Runs But Doesn’t Move Waste

This common issue typically indicates one of several problems:

- Air leak in the intake line: Check all connections between the holding tank and pump for tightness.

- Clogged intake: Inspect the tank outlet and intake hose for blockages.

- Worn impeller: After extended use, the rubber impeller can wear down, reducing pumping efficiency.

- Dry pump: Some macerator pumps need to be primed with water before operation.

Solution: Verify all connections are tight, clear any blockages, and if necessary, prime the pump with water. If the impeller is worn, a replacement kit is readily available.

Problem 2: Pump Makes Noise But Doesn’t Run Properly

This situation often points to:

- Partial blockage: Something is impeding the cutter or impeller movement.

- Low voltage: The pump isn’t receiving sufficient power.

- Worn bearings: The motor bearings may be failing.

- Damaged cutter plate: The grinding mechanism may be compromised.

Solution: Check your electrical system to ensure proper voltage (typically 12V with minimal voltage drop under load). Inspect for blockages by disconnecting and examining the pump. If bearings or the cutter plate are damaged, replacement parts or a new pump may be necessary.

Problem 3: Pump Doesn’t Turn On At All

When your pump shows no signs of life:

- Electrical issues: Check fuses, connections, and switches.

- Seized motor: Internal components may be locked up.

- Thermal overload: The pump may have overheated and shut down.

Solution: First, verify the electrical system—replace blown fuses, check wiring for continuity, and test the switch. If the motor is seized, sometimes a gentle tap can free it, but often replacement is necessary. For thermal overload, allow the pump to cool completely before attempting operation again.

Problem 4: Pump Runs But Leaks

Leaks indicate:

- Cracked housing: The pump body may have been damaged or weakened.

- Loose connections: Hose clamps may have loosened over time.

- Failed seals: Internal seals may have deteriorated.

Solution: Tighten all connections and replace any damaged hoses. If the pump housing is cracked or seals have failed, replacement is typically the most cost-effective solution.

Remember that prevention is always easier than troubleshooting. Regular inspection and maintenance will catch many issues before they become serious problems.

Keeping It Clean: Proper Maintenance of Your Macerator Pump

A well-maintained macerator pump can provide years of reliable service. Establishing a regular maintenance routine not only extends the life of your pump but also prevents those inconvenient failures that inevitably occur at the worst possible moments.

Regular Flushing

The simplest yet most effective maintenance practice is regular flushing. After emptying your holding tank, run fresh water through the system to clear residual waste. This prevents buildup that can harden and cause blockages or damage to the cutting mechanism.

To perform a proper flush:

- Empty the holding tank completely.

- Add several gallons of fresh water to the tank.

- Run the macerator pump until clear water emerges from the discharge.

- For extra cleanliness, add a marine-safe tank cleaner to the flush water occasionally.

This practice should become part of your routine after each holding tank discharge.

Seasonal Inspection

At least twice a year (typically at the beginning and end of boating season), perform a more thorough inspection:

- Disconnect the pump and check for any visible damage or wear.

- Inspect hoses for signs of cracking, softening, or wear—particularly at connection points.

- Verify all electrical connections are tight and free from corrosion.

- Check mounting hardware for security.

- Listen for unusual sounds during operation that might indicate worn bearings or other internal issues.

Winterization

For boaters in seasonal climates, proper winterization is essential to prevent freeze damage:

- Empty the holding tank completely.

- Flush the system thoroughly with fresh water.

- Add non-toxic antifreeze to the tank and run it through the macerator pump.

- Disconnect and drain any lines that might hold water.

- In extreme climates, consider removing the pump entirely and storing it in a temperature-controlled environment.

Preventative Parts Replacement

Even with perfect maintenance, certain components have a limited lifespan. Consider proactively replacing:

- The impeller every 2-3 years (or sooner if performance declines)

- Seals and gaskets if any signs of weeping or leakage appear

- The cutter assembly if grinding efficiency decreases

Many experienced boaters keep a rebuild kit or even a complete spare pump on board for extended cruises. The cost of these spares is minimal compared to the inconvenience of a failure while away from service facilities.

Common Problems with Jabsco Macerator Pumps and Their Solutions

Despite their robust design, Jabsco macerator pumps can develop specific issues over time. Understanding these common problems helps you address them quickly when they arise.

Clogging Issues

The most frequent complaint involves clogging, often caused by inappropriate items entering the system. While macerator pumps can handle human waste and toilet paper, they aren’t designed for:

- Feminine hygiene products

- Paper towels or “flushable” wipes (which aren’t truly flushable in marine systems)

- Hair accumulation

- Hard objects that accidentally enter the toilet

Solution: Install a waste strainer before the pump to catch problematic items, and educate all boat users about what can and cannot go into the marine toilet. For existing clogs, disconnecting and clearing the pump may be necessary.

Motor Burnout

Running the pump dry or allowing it to operate against a blockage can cause motor burnout. This typically happens when:

- The holding tank is empty but the pump continues to run

- A discharge line is blocked or kinked

- The pump runs continuously for too long

Solution: Always monitor the pump during operation, and install a timer switch that automatically cuts power after a set period (typically 2-3 minutes). Never leave the pump running unattended.

Impeller Failure

The rubber impeller inside the pump can deteriorate over time, especially if:

- The system runs dry frequently

- Harsh chemicals are used in the holding tank

- The impeller has simply aged

Solution: Replace the impeller at the first sign of decreased pumping efficiency. Replacement kits are relatively inexpensive and simple to install with basic tools.

Electrical Problems

Marine environments are notoriously harsh on electrical components. Common electrical issues include:

- Corroded connections leading to intermittent operation

- Voltage drop causing sluggish performance

- Switch failure from repeated use

Solution: Use marine-grade tinned wire for all connections, apply dielectric grease to terminals, and consider upgrading to sealed switches designed for wet environments. Verify proper fuse protection to prevent electrical damage.

Vibration Damage

Excessive vibration can loosen mountings and connections over time. This is particularly common in planing boats or those that frequently encounter rough water.

Solution: Mount the pump on vibration-absorbing material, regularly check and tighten all mounting hardware, and use flexible sections of hose on both inlet and outlet to absorb movement.

By recognizing these common issues early and addressing them promptly, you’ll maximize the reliability and lifespan of your Jabsco macerator pump.

The Buying Guide: Selecting the Right Jabsco Macerator Pump

When it’s time to purchase a new macerator pump or replace an existing one, several considerations will guide your selection process. Jabsco offers multiple models with varying features and capabilities to match different boating needs.

Popular Jabsco Macerator Models

- Jabsco 18590-Series: The standard workhorse, this model offers reliable performance for most recreational boats. It features a flow rate of approximately 12 gallons per minute and operates on 12V DC power.

- Jabsco 18590-2092: An upgraded version with a more powerful motor, suitable for applications requiring higher head pressure or longer discharge runs.

- Jabsco 18555-Series: A compact model designed for installations with limited space, offering similar performance to the standard models but in a smaller package.

- Jabsco Heavy-Duty Models: For larger vessels or commercial applications, these models offer enhanced durability and higher flow rates.

Selection Criteria

When choosing your pump, consider:

- Tank size: Larger holding tanks benefit from higher-capacity pumps.

- Discharge distance: Longer or higher discharge paths require more powerful models.

- Frequency of use: Boats with multiple users or liveaboards should consider heavy-duty models.

- Available space: Measure your installation area to ensure proper fit.

- Power availability: Verify your electrical system can support the amp draw of your chosen model.

Where to Purchase

Jabsco macerator pumps are widely available through:

- Marine supply stores like West Marine or Defender

- Online retailers such as Amazon or eBay

- Direct from marine equipment distributors

- Local boat service centers and chandleries

Many experienced boaters recommend purchasing from specialized marine retailers rather than general online marketplaces, as you’re more likely to receive the correct model with proper warranty coverage.

Price Range Expectations

As of 2025, pricing for Jabsco macerator pumps typically falls within these ranges:

- Standard models: $150-$200

- Heavy-duty models: $200-$300

- Rebuild kits: $40-$60

- Complete replacement parts: Varies by component, typically $20-$100

While it might be tempting to save money with non-branded alternatives, the reliability and availability of replacement parts make genuine Jabsco pumps worth the investment for most boaters. The cost of quality equipment is always less than the expense of failures at inopportune moments.

Advanced Maintenance: Replacing the Impeller

The impeller is the component most likely to require replacement during your pump’s lifespan. This rubber part creates the suction that draws waste from your holding tank, and it naturally wears over time. Knowing how to replace it can save you a service call and get your system back in operation quickly.

Tools needed:

- Screwdriver set

- Adjustable wrench

- Replacement impeller kit (specific to your pump model)

- Clean rags

- Waterproof grease

- Rubber gloves

Step-by-step procedure:

- Disconnect power: Always disconnect the power source before beginning any work on the pump. Remove the fuse or disconnect the battery to ensure safety.

- Remove pump: Disconnect the hoses from the pump after closing any valves in the system. Unscrew the mounting bolts and move the pump to a clean work area.

- Open the housing: Remove the screws holding the pump body together. Different Jabsco models have varying designs, but most feature multiple screws around the perimeter of the housing.

- Access the impeller: Carefully separate the housing halves to expose the impeller. Take note of the orientation of all components for reassembly.

- Remove old impeller: The impeller is typically pressed onto the motor shaft or secured with a small setscrew. Gently pry it off or loosen the setscrew to remove it.

- Inspect other components: While the pump is open, check the cutter plate, housing, and other components for wear or damage. This is an ideal time to replace any questionable parts.

- Install new impeller: Apply a small amount of waterproof grease to the motor shaft and press the new impeller into place. Ensure it’s fully seated and properly aligned.

- Reassemble: Carefully reassemble the pump housing, making sure gaskets or O-rings are properly positioned. Tighten screws evenly in a crisscross pattern to ensure proper sealing.

- Reinstall and test: Mount the pump back in position, reconnect hoses and electrical connections, and test with clean water to verify proper operation before returning to service.

This maintenance procedure typically takes 30-45 minutes and should be performed whenever you notice decreased pumping efficiency or at recommended service intervals (typically every 2-3 years for recreational boats).

Solid Handling Capabilities: What Can Your Pump Process?

One of the most frequent questions about macerator pumps concerns their ability to handle solid materials. Jabsco designs their pumps specifically to process normal marine toilet waste, but understanding the limitations helps prevent issues.

Jabsco macerator pumps excel at processing human waste and toilet paper, the two materials they encounter most frequently. The cutting mechanism efficiently reduces these to a slurry that passes easily through discharge hoses without clogging.

However, these pumps have definite limitations. They are not designed to handle:

- Sanitary products: Feminine hygiene products, even those marketed as flushable, can wrap around the cutter and jam the mechanism.

- Cleaning wipes: Disposable cleaning wipes contain synthetic fibers that resist breaking down and can cause stubborn clogs.

- Paper towels: The long fibers in paper towels can tangle in the cutting mechanism.

- Foreign objects: Anything not intended for flushing (dental floss, cotton swabs, etc.) can cause serious damage.

- Excessive hair: Large amounts of hair can wrap around moving parts and reduce efficiency.

For optimal performance, many experienced boaters install a waste strainer or filter before the macerator pump. These devices catch problematic materials before they reach the pump, preventing damage and extending service life.

If your system must handle more demanding applications, consider upgrading to a heavy-duty model designed for commercial use. These pumps feature more robust cutting mechanisms and more powerful motors, allowing them to process a wider range of materials.

Remember that the best approach is prevention—educate everyone aboard about what can and cannot enter the marine toilet. A simple sign in the head reminding users of these limitations can prevent most problems before they occur.

Vessel Requirements: Does Your Boat Need a Macerator Pump?

Not all boats require a macerator pump, but many benefit significantly from having one installed. Understanding your specific needs helps you make an informed decision about this equipment.

Boats That Typically Require Macerator Pumps:

- Vessels with holding tanks: If your boat has a waste holding tank (required in many waters), a macerator pump provides a legal means of discharge when appropriate.

- Cruising boats: Vessels that travel beyond easy reach of pump-out facilities often benefit from the ability to discharge treated waste in legal offshore areas.

- Liveaboards: Boats used as primary residences generate more waste and benefit from flexible disposal options.

- Larger recreational boats: Vessels with extended range or multiple heads typically incorporate macerator pumps into their waste management systems.

Boats That May Not Need Macerator Pumps:

- Portable toilet users: Small boats using portable chemical toilets typically empty these units at shoreside facilities.

- Day sailors: Boats used exclusively for short trips may rely entirely on marina facilities.

- Vessels with composting toilets: Alternative toilet systems may eliminate the need for conventional waste processing.

- Boats in areas with comprehensive pump-out networks: In regions with abundant, convenient pump-out facilities, some boaters choose to rely exclusively on these services.

The decision often comes down to how and where you use your boat. Even if not strictly necessary, a macerator pump provides valuable flexibility and emergency options that many boaters appreciate having available.

Local regulations also play a significant role in this decision. In some areas, particularly sensitive waterways or marine sanctuaries, discharge may be prohibited entirely, reducing the utility of a macerator pump. Always research the regulations in your primary cruising grounds before making this investment.

Seasonal Care: Winterizing Your Jabsco Macerator Pump

For boaters in seasonal climates, proper winterization is essential to prevent costly damage from freezing temperatures. A well-winterized macerator pump will be ready for service when boating season returns.

The winterization process for Jabsco macerator pumps involves several key steps:

- Complete system emptying: Begin by emptying your holding tank completely using the pump or a pump-out facility.

- Thorough flushing: Add several gallons of fresh water to the holding tank and run the macerator pump to flush out any remaining waste material.

- Antifreeze protection: Pour RV/marine antifreeze (propylene glycol, not toxic ethylene glycol) into the holding tank. The amount varies by system size, but typically 2-4 gallons provides adequate protection.

- Circulate antifreeze: Run the macerator pump until you see the colored antifreeze emerging from the discharge. This ensures all pump components and discharge hoses are protected.

- Power disconnection: Remove the fuse or disconnect the power leads to the pump to prevent accidental operation during storage.

- Optional removal: In extremely cold climates, consider removing the pump entirely and storing it in a temperature-controlled environment.

- Discharge closure: Ensure the discharge seacock is closed to prevent water intrusion during the off-season.

- Documentation: Make notes about the condition of the pump and any maintenance that might be needed before recommissioning in spring.

This winterization process typically takes 30-60 minutes and represents a small investment of time compared to the cost of replacing a pump damaged by freezing. Many boaters combine macerator pump winterization with other end-of-season tasks for efficiency.

When spring arrives, recommissioning is similarly straightforward:

- Inspect all hoses and connections for cracks or damage.

- Verify all seacocks open and close properly.

- Reconnect power and test the pump with fresh water before actual use.

- Check for leaks or unusual noises during operation.

With proper seasonal care, your Jabsco macerator pump should provide reliable service for many boating seasons.

Enhancing Performance: Accessories for Your Macerator System

Several accessories can improve the functionality, convenience, and reliability of your macerator pump system. These add-ons range from simple convenience features to important safety enhancements.

Popular Accessories Include:

- Timer Switches: These automatically cut power after a preset duration (typically 2-3 minutes), preventing accidental extended operation that could damage the pump or discharge in prohibited areas.

- Y-Valves: Allow selection between discharge destinations (holding tank or direct discharge where legal), providing system flexibility.

- Strainers: Installed before the macerator pump, these catch debris that could damage the cutting mechanism, extending pump life.

- Anti-Siphon Valves: Prevent backflow into the holding tank or boat interior if the discharge hose is below the waterline.

- Vented Loops: Essential for installations where the discharge thru-hull is near or below the waterline, preventing water intrusion.

- Tank Level Indicators: Provide accurate information about holding tank capacity, helping avoid overfilling or running the pump dry.

- Discharge Indicators: Visual or audible alerts when the pump is operating, reducing the risk of accidental discharge.

- Odor Control Filters: While not directly related to the pump, these can make the entire waste system more pleasant to live with.

When selecting accessories, focus on quality marine-grade components designed for the harsh conditions found on boats. Lower-quality alternatives often fail prematurely in the marine environment.

Installation of these accessories should follow manufacturer guidelines, with particular attention to electrical connections and hose routing. When in doubt, consult a marine technician for proper installation, especially for safety-related components like vented loops or anti-siphon valves.

Preventing Blockages: Proactive Maintenance Strategies

Blockages represent the most common and frustrating issues with macerator systems. Fortunately, several proactive strategies can dramatically reduce their occurrence.

Education and Prevention

The most effective approach starts with education. Ensure everyone aboard understands what can and cannot enter the marine toilet. Consider posting a simple list in each head:

- Acceptable: Human waste, marine toilet paper (sparingly)

- Never Acceptable: Sanitary products, paper towels, wipes, dental floss, hair, food waste

Regular System Flushing

Develop a habit of regular system flushing to prevent waste buildup:

- After each holding tank discharge, add fresh water to the tank.

- Run the macerator pump until clear water emerges from the discharge.

- Consider adding a marine-safe tank treatment that helps break down solids.

Strategic Installation

Certain installation practices can minimize blockage risks:

- Use the largest practical diameter hoses allowed for your pump model.

- Avoid sharp bends or dips in discharge hoses where material can accumulate.

- Install the pump with proper vertical orientation according to manufacturer specifications.

- Consider a pre-pump strainer to catch problematic materials before they reach the macerator.

Regular Inspection

Develop a regular inspection routine:

- Check inlet and outlet connections for restrictions or damage.

- Inspect hoses for soft spots, kinks, or sagging sections.

- Listen for changes in pump sound that might indicate partial blockages.

- Verify proper voltage during operation to ensure the pump has adequate power.

By implementing these preventative measures, you’ll significantly reduce the likelihood of blockages and extend the service life of your entire waste management system. Remember that prevention is always easier and less unpleasant than clearing blockages after they occur.

Technical Specifications: Understanding Flow Rates and Performance

For those interested in the technical aspects of macerator pumps, understanding flow rates and performance metrics helps in selecting the right model for your specific application.

Standard Jabsco macerator pumps typically offer flow rates between 12-15 gallons per minute (GPM) under ideal conditions. This rate varies based on several factors:

- Vertical lift: Performance decreases as the vertical distance from pump to discharge point increases. Most models can manage 10-12 feet of lift, but flow rates decrease significantly at maximum lift.

- Discharge length: Longer discharge hose runs create more resistance, reducing flow rates. For runs exceeding 20 feet, consider larger diameter hoses or more powerful pump models.

- Voltage supply: Pumps operate most efficiently at their rated voltage. A 12V pump receiving only 11V due to wiring losses may experience up to 20% reduction in performance.

- Waste consistency: Thicker waste requires more power and pumps more slowly than diluted waste.

Typical performance specifications for standard Jabsco macerator pumps include:

- Flow Rate: 12-15 GPM at zero lift

- Maximum Lift: 10-12 feet vertical

- Self-Priming: Up to 4 feet vertical suction lift

- Current Draw: 10-15 amps at 12V DC (varies by model)

- Discharge Port: 1-inch or 1.5-inch hose barb

- Inlet Port: 1.5-inch hose barb

- Motor Protection: Thermal overload (most models)

- Duty Cycle: Intermittent (typically 15 minutes maximum continuous operation)

When planning your installation, always account for “real-world” conditions rather than maximum specifications. A pump rated for 15 GPM might deliver only 10 GPM in a typical boat installation with some vertical lift and hose runs.

For optimal performance, size your pump generously for your application—a pump operating at 70% of its maximum capacity will typically last longer and experience fewer issues than one constantly running at its limits.

Beyond Boats: Using Jabsco Macerator Pumps in RVs

While primarily designed for marine applications, Jabsco macerator pumps have found popularity in the RV community as well. The principles remain similar, but there are important considerations specific to RV use.

RV Applications

In recreational vehicles, macerator pumps serve several valuable functions:

- Emptying holding tanks: When conventional gravity dump systems aren’t practical or available.

- Extending discharge distance: Allowing connection to distant sewer connections without repositioning the RV.

- Uphill discharge: Enabling waste discharge to higher-elevation sewer connections.

- Cleaner operation: Providing a more contained waste transfer compared to traditional RV dump hoses.

Installation Differences

RV installations differ from marine applications in several key ways:

- Power considerations: Many RVs operate on 12V DC when boondocking but can use 120V AC when connected to shore power. Consider a pump compatible with your primary power source.

- Freeze protection: RVs often travel through varying climates, requiring more comprehensive freeze protection systems.

- Discharge regulations: Unlike marine environments, RV waste must always be discharged into approved dump facilities, never onto ground or into storm drains.

- Connection adaptability: RV installations benefit from quick-connect fittings that allow attachment to standard sewer connections.

Popular RV-specific accessories include:

- Extendable discharge hoses

- Sewer connection adapters

- Storage containers for the discharge system

- Quick-connect electrical plugs for temporary installations

Many RV owners install their macerator pumps as portable systems rather than permanent fixtures, allowing flexibility in discharge locations and easier storage when not in use.

If you’re considering a Jabsco macerator pump for your RV, select models specifically marketed for RV use or consult with an RV service center about the best configuration for your particular vehicle and travel style.

Longevity Expectations: How Long Will Your Pump Last?

One of the most common questions about macerator pumps concerns their expected lifespan. While individual experiences vary based on usage patterns and maintenance practices, some general guidelines can help set realistic expectations.

With proper installation and regular maintenance, a quality Jabsco macerator pump typically provides 5-7 years of reliable service in recreational applications. Commercial or liveaboard use may reduce this timeframe due to more frequent operation.

Several factors significantly influence longevity:

Factors That Extend Pump Life:

- Regular flushing with fresh water after each use

- Proper electrical supply with correct fuse protection

- Preventing dry running by monitoring tank levels

- Seasonal maintenance including winterization where appropriate

- Prompt attention to unusual noises or performance changes

- Installation of a pre-pump strainer to catch debris

- Operating within duty cycle limitations (avoiding extended continuous use)

Factors That Shorten Pump Life:

- Improper materials entering the system (wipes, sanitary products, etc.)

- Running the pump dry repeatedly

- Electrical issues like voltage fluctuations or improper wiring

- Freeze damage from inadequate winterization

- Infrequent use without proper flushing

- Harsh chemicals in the holding tank

- Continuous operation beyond recommended duty cycle

Many experienced boaters follow a preventative replacement schedule, rebuilding or replacing their macerator pump every 3-5 years regardless of performance. This approach minimizes the risk of failures during critical times or in remote locations.

The cost of scheduled maintenance is minimal compared to the inconvenience of emergency repairs, especially considering that pump failures rarely occur at convenient times or locations. As the saying goes among seasoned boaters: “The sea finds every weakness”—a philosophy that applies perfectly to marine sanitation systems.

Conclusion: Mastering Your Marine Sanitation System

Throughout this comprehensive guide, we’ve explored every aspect of Jabsco macerator pumps—from basic functions to advanced troubleshooting. The knowledge you’ve gained represents a valuable addition to your boating expertise, enabling you to maintain this critical system with confidence.

Remember that proper waste management is not just about convenience—it’s about environmental responsibility and regulatory compliance. A well-maintained macerator pump gives you the technical capability to manage waste properly, but the responsibility for legal and ethical discharge remains with you, the vessel operator.

As you apply this knowledge to your own boat, consider developing a regular maintenance schedule that includes:

- System flushing after each holding tank discharge

- Monthly inspection of hoses and connections

- Seasonal checks of electrical components

- Annual impeller inspection

- Complete winterization in seasonal climates

This proactive approach will maximize reliability while minimizing unpleasant surprises—a worthwhile investment for any system related to waste management!

Whether you’re installing your first macerator pump or troubleshooting an existing system, the information in this guide provides a solid foundation for success. Combine this knowledge with manufacturer instructions specific to your model, and you’ll enjoy years of trouble-free operation from your marine sanitation system.

Happy boating, and may your waste management system remain as reliable and forgettable as possible—because when it comes to macerator pumps, boring reliability is exactly what we’re aiming for.